Enterprise Tool Management & Tracking

Gain visibility and operational control over your tool inventory – from the warehouse to the field and back.

Manage Tools Across Stocking Locations & Job Sites

Seamless Asset Transfers

Transfer tools across sites with near-real-time updates to inventory amounts and location.

Multiple Reporting Points

Reflect your organization’s structure and gain enterprise-wide visibility with data rollup from multiple locations.

User-Defined Templates

Boost consistency and replicability by creating standardized lists for kits, pick tickets, and purchase orders.

100% Digital

Service & Calibration

Improve safety and extend tool life with service forecasting, automated service notifications, and maintenance records.

Reduce Costs, Boost Productivity & Accountability

Streamline Workflows

Drive Profitability & Productivity

Instill Accountability

An Integrated Tool Management System

Unified Dashboard

Real-Time Inventory Updates

Barcode and RFID Integration

GPS and Bluetooth Tracking

Custom Alerts and Notifications

Customer Testimonials

-

"Align provides a customizable way to inventory tools by location and easily transfer, retire, and regulate tools."

Elizabeth C.

-

"We can quickly see where all our assets are and make sure the jobs won’t experience delays if they need anything."

Vinny Fattorusso

Inventory Manager, Hillis -

"Accuracy in the warehouse has improved. I can’t even put into words how much it has improved."

Tina Helmsing

Controller, Guarantee Electrical Company

The Evolution of Enterprise Tool Management

Scalable Solutions for Growing Businesses

Comprehensive Audit Trails

Integration with ERP Systems

Customizable User Permissions

Advanced Analytics and Reporting

Get Up and Running Quickly

Our implementation team partners with every new customer to configure the Align enterprise tool management system for your unique needs and to get up and running quickly so you can stay focused on getting your projects done.

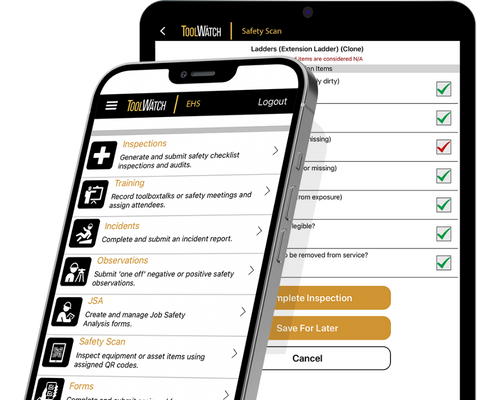

See How ToolWatch EHS Equips Your Construction Safety Program Today

About ToolWatch EHS

1. Will ToolWatch EHS replace Safety Reports?

Safety Reports will continue to be a separate product. ToolWatch EHS is designed for the construction industry, while Safety Reports remain a point solution serving a broader customer base.

2. Our company currently pays for separate ToolWatch and Safety Reports accounts. Can they be merged?

Yes, you can use one login for both ToolWatch and ToolWatch EHS. We will work with you to port your Safety Reports users to ToolWatch EHS so you can take advantage of the benefits of using ToolWatch and EHS together.

3. Does ToolWatch EHS data integrate with Vista? For example, are job or employee data available in EHS from Vista like it is for ToolWatch?

Currently, the primary integration that ToolWatch EHS has is with Procore and PlanGrid. However, we are working so that in the future both ToolWatch and ToolWatch EHS will have the same integration capability.

4. Does ToolWatch EHS offer live tracking of individuals on a job site?

ToolWatch EHS does not not track individuals in real time. However, we make it simple for users to input geotag locations for where they’re performing inspections, observations, or other safety functions. Combined with our time-stamping capabilities, geotag data show when and where certain safety processes are occurring.

5. ToolWatch EHS content is tailored to OSHA standards. Is there a plan to adopt other countries’ standards?

Currently, ToolWatch EHS content focuses on OSHA standards. We are looking to expand our checklist capabilities with additional checklists, detailed comprehensive data and documentation in the future.

6. If a manufacturer has specific inspection requirements, can those be used to direct the inspections for safety equipment?

Yes. Users can customize the inspection checklists and the frequency that you inspect a certain piece of equipment.

7. Will ToolWatch and ToolWatch EHS be accessed with separate mobile apps, or will they be combined?

Today, there is an EHS mobile app and a ToolWatch mobile app, but we plan to have one unified app in the future.

8. What type of access control measures does ToolWatch EHS have?

ToolWatch EHS has controls based on permissions and entitlements. Users can be granted access to individual safety module(s) and/or associated administrative functions.

9. What is the pricing structure for ToolWatch EHS?

The ToolWatch EHS modules come bundled in three different tiers depending on the needs of your safety program. We can work with you to figure out what tier and what modules make sense for you.

10. Can you upload custom sheets/cards for the Toolbox Talks?

Yes. In addition to a library of hundreds of Toolbox Talks that are free for users, companies can upload custom PDF Toolbox Talks to the EHS Training module.

11. Why does ToolWatch EHS use QR codes rather than barcodes?

We are focusing on QR codes because we believe they offer more capability and flexibility to store inspection history and other asset information.

14. Does ToolWatch EHS allow users to track and report on the completion of weekly Toolbox Talks for their crews?

Yes. The ToolWatch EHS Training module allows you to see if scheduled Toolbox Talks have been completed and offers multiple detailed reports that let you filter that information by user and user group.

15. Can ToolWatch EHS be purchased separately from ToolWatch Cloud?

Yes, you can use ToolWatch EHS even if you do not use ToolWatch for other functions.

16. Can Safety Reports data be exported to ToolWatch EHS?

Yes. Any existing Safety Reports data will remain available once you transition to ToolWatch EHS.

Frequently Asked Questions

What is a tool management system?

A tool management system is a software solution designed to track, manage, and maintain tools and equipment across various locations. A tool management system provides real-time visibility into tool inventory, reduces losses, and improves overall efficiency in managing construction assets.

How does an enterprise tool management solution benefit construction companies?

Enterprise tool management solutions offer construction companies – not just large businesses, but also sub-contractors, and self-performing general contractors of all sizes – centralized control over their entire inventory of tools and equipment. It ensures all assets are tracked and maintained properly, reduces downtime, and enhances operational efficiency. This system integrates with other enterprise systems to provide comprehensive insights and streamline operations across multiple job sites and warehouses.

What features does Align's construction tool management system offer?

Align's construction tool management system includes features such as real-time tracking, automated asset transfers, GPS, Bluetooth and RFID support, maintenance management, and employee certification management. These features help ensure tools are available when needed, maintained regularly, and used by certified personnel.

Can Align’s construction tool management system integrate with our existing software?

Yes, Align's Construction Tool Management system is designed to integrate seamlessly with your existing ERP, accounting, and project management software. This integration helps streamline data flow, improve accuracy, and enhance overall operational efficiency.

How does a tool management system improve accountability?

The tool management system improves accountability by providing detailed audit trails that document tool transfers, requisitions, and returns. This ensures that every movement of tools and equipment is tracked, reducing the risk of loss or theft and promoting a culture of responsibility among workers.