Wireless Tool Tracking

Take control of the assets your teams need to get the job done.

Automatically and Wirelessly Track All Your Tools and Equipment

in the Leading Construction Operations Platform

Align Wireless Tracking delivers accurate, timely asset location data in a platform that enables team collaboration, improves operational efficiency, and unlocks breakthrough productivity.

Real-Time Asset Location

Automated Asset Transfers

Efficient Inventory Management

Automated Job Cost & Billing

Powerful Reporting & Analytics

Leverage reports to spot discrepancies between assigned and scanned locations, and proactively manage asset loss through real-time monitoring.

Less Time Searching, More Time Doing

Fuel Project Success

Boost Field Visibility

Reduce Asset Loss

BLUETOOTH TOOL TRACKING FOR EFFICIENCY

Streamlined Tool Management

Bluetooth tool tracking simplifies the management of your tools and equipment, helping you quickly locate any item within your warehouse or job site. This significantly reduces the time spent searching for tools, ensuring your team remains productive and focused on the task at hand.

Real-Time Updates

Align's Bluetooth asset tracking provides real-time updates on the location of your tools. As assets move through different areas, Bluetooth gateways automatically capture their positions, offering instant visibility and ensuring that records are always current and accurate.

Seamless Integration with ERP Systems

Integrate Align’s Bluetooth tool tracking data directly into your existing ERP and accounting systems. This integration reduces manual data entry errors, ensures accurate job costing, and streamlines the billing process. By automating these workflows, your back-office operations become more efficient, allowing your team to focus on higher-value tasks.

Enhanced Security and Accountability

With Align wireless tracking, you can set up alerts for unauthorized movements or if a tool leaves a designated area. This feature enhances security, reduces the risk of theft, and promotes accountability among your team members, ensuring that all tools are used responsibly.

Track Anything, Anywhere

A Platform You Can Build On

Your Construction Ops Control Center

Align brings all your operations data together in a single platform and integrates it with other business systems to power the operations that support your projects.

No Vendor Lock-In

Track all of your tools and equipment, regardless of manufacturer, with the best combination of wireless gateways and tags for your job sites and warehouses.

Enterprise Secure & Scalable

Remotely manage your wireless tracking gateways without compromising your IT network, and access the data on Align, which passed the SOC 2 Type 2 security audit.

ADVANCED BLUETOOTH ASSET TRACKING

Precision Tracking with Bluetooth Gateways

Align’s advanced Bluetooth asset tracking technology utilizes a network of Bluetooth gateways to provide precise location data. This system ensures that you always know where your tools are, whether they are on-site or in the warehouse. The detailed tracking capabilities help you manage your inventory more effectively, reducing downtime and improving project timelines.

Scalable Wireless Tool Tracking Solutions

Our wireless tool tracking solutions are scalable, making them ideal for businesses of any size. Whether you have a small inventory or thousands of assets, Align’s system can grow with your needs. The scalable nature of our Bluetooth tool tracking ensures that you can maintain control over your assets as your business expands.

Customizable Alerts and Notifications

Set up customizable alerts and notifications for various events, such as tool check-ins, check-outs, and maintenance needs. These notifications help keep your team informed and proactive, ensuring that all tools are available when needed and properly maintained. This proactive approach reduces the likelihood of unexpected breakdowns and extends the lifespan of your tools.

Data-Driven Decision Making

Leverage the data collected through Align wireless tracking to make informed decisions about your tool inventory. Analyze usage patterns, identify underutilized assets, and make strategic decisions about purchases and deployments. This data-driven approach ensures that you are maximizing the value of your investments and optimizing your operations.

Elevate Operations Across All Departments

Warehouse

- Eliminate time wasted searching and inventorying assets.

- Improve project resourcing with accurate asset count and location data.

- Better support projects and improve relationships with the field and back office.

Field

- Eliminate the need for foremen or superintendents to hunt down every tool on site.

- Ensure assets are accurately charged to your job without the need to verify manually.

Back Office

- Automatically associate items with jobs to accurately cost and bill your assets.

[Case Study Name]

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

ALIGN WIRELESS TRACKING IN ACTION

Improved Operational Efficiency

Align wireless tracking transforms the way you manage your tools and equipment. By providing real-time location data and automated updates, our system eliminates the need for manual inventory checks, saving time and reducing errors. This efficiency translates into better project execution and higher overall productivity.

Cost Savings

Implementing Align’s Bluetooth tool tracking system can lead to significant cost savings. By reducing tool loss and theft, optimizing inventory levels, and minimizing downtime, you can lower your operational costs. Additionally, integrating Align with your existing ERP systems ensures accurate job costing and billing, further improving your financial management.

User-Friendly Interface

Align’s platform features a user-friendly interface that makes it easy for your team to use. Whether they are in the field, in the warehouse, or in the office, team members can quickly access the information they need. The intuitive design reduces the learning curve and ensures that everyone can effectively manage their responsibilities.

![]()

Get Up and Running Quickly

Our implementation team partners with every new customer to configure Align for your unique needs and to get up and running quickly so you can stay focused on getting your projects done.

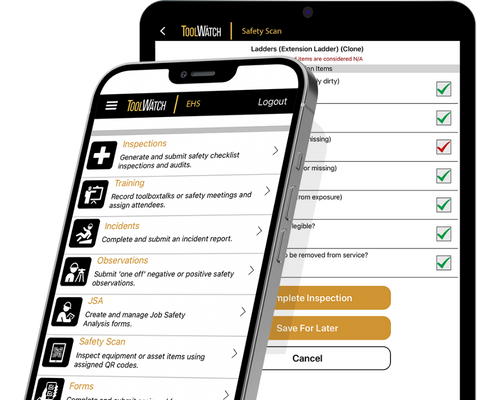

See How ToolWatch EHS Equips Your Construction Safety Program Today

About ToolWatch EHS

1. Will ToolWatch EHS replace Safety Reports?

Safety Reports will continue to be a separate product. ToolWatch EHS is designed for the construction industry, while Safety Reports remain a point solution serving a broader customer base.

2. Our company currently pays for separate ToolWatch and Safety Reports accounts. Can they be merged?

Yes, you can use one login for both ToolWatch and ToolWatch EHS. We will work with you to port your Safety Reports users to ToolWatch EHS so you can take advantage of the benefits of using ToolWatch and EHS together.

3. Does ToolWatch EHS data integrate with Vista? For example, are job or employee data available in EHS from Vista like it is for ToolWatch?

Currently, the primary integration that ToolWatch EHS has is with Procore and PlanGrid. However, we are working so that in the future both ToolWatch and ToolWatch EHS will have the same integration capability.

4. Does ToolWatch EHS offer live tracking of individuals on a job site?

ToolWatch EHS does not not track individuals in real time. However, we make it simple for users to input geotag locations for where they’re performing inspections, observations, or other safety functions. Combined with our time-stamping capabilities, geotag data show when and where certain safety processes are occurring.

5. ToolWatch EHS content is tailored to OSHA standards. Is there a plan to adopt other countries’ standards?

Currently, ToolWatch EHS content focuses on OSHA standards. We are looking to expand our checklist capabilities with additional checklists, detailed comprehensive data and documentation in the future.

6. If a manufacturer has specific inspection requirements, can those be used to direct the inspections for safety equipment?

Yes. Users can customize the inspection checklists and the frequency that you inspect a certain piece of equipment.

7. Will ToolWatch and ToolWatch EHS be accessed with separate mobile apps, or will they be combined?

Today, there is an EHS mobile app and a ToolWatch mobile app, but we plan to have one unified app in the future.

8. What type of access control measures does ToolWatch EHS have?

ToolWatch EHS has controls based on permissions and entitlements. Users can be granted access to individual safety module(s) and/or associated administrative functions.

9. What is the pricing structure for ToolWatch EHS?

The ToolWatch EHS modules come bundled in three different tiers depending on the needs of your safety program. We can work with you to figure out what tier and what modules make sense for you.

10. Can you upload custom sheets/cards for the Toolbox Talks?

Yes. In addition to a library of hundreds of Toolbox Talks that are free for users, companies can upload custom PDF Toolbox Talks to the EHS Training module.

11. Why does ToolWatch EHS use QR codes rather than barcodes?

We are focusing on QR codes because we believe they offer more capability and flexibility to store inspection history and other asset information.

14. Does ToolWatch EHS allow users to track and report on the completion of weekly Toolbox Talks for their crews?

Yes. The ToolWatch EHS Training module allows you to see if scheduled Toolbox Talks have been completed and offers multiple detailed reports that let you filter that information by user and user group.

15. Can ToolWatch EHS be purchased separately from ToolWatch Cloud?

Yes, you can use ToolWatch EHS even if you do not use ToolWatch for other functions.

16. Can Safety Reports data be exported to ToolWatch EHS?

Yes. Any existing Safety Reports data will remain available once you transition to ToolWatch EHS.

Frequently Asked Questions

What is Bluetooth tool tracking and how does it work?

Bluetooth tool tracking uses Bluetooth technology to monitor the location and status of tools in real-time. Small Bluetooth tags are attached to the tools, which then communicate with Bluetooth gateways to provide location data. This information is collected and displayed in a central software system, allowing for easy tracking and management of assets.

How does Bluetooth asset tracking improve inventory management?

Bluetooth asset tracking improves inventory management by providing real-time updates on the location and status of assets. This reduces the time spent searching for tools and equipment, minimizes losses, and ensures that all assets are accounted for. The system also helps in maintaining accurate inventory records, which can be critical for planning and resource allocation.

What are the advantages of using wireless tool tracking for construction projects?

Using wireless tool tracking for construction projects offers several advantages, including increased efficiency, reduced downtime, and enhanced asset visibility. It allows for the quick location of tools on large job sites, automates asset transfers, and ensures that equipment is always where it is needed. This leads to more streamlined operations and improved project timelines.

How does Align wireless tracking integrate with existing systems?

Align wireless tracking integrates seamlessly with existing systems that your business uses every day, including ERP, accounting, and project management software. This integration allows for the smooth flow of data between systems, improving overall operational efficiency and enabling better decision-making based on accurate, real-time information.

Can Align wireless tracking be used in harsh environments?

Yes, Align wireless tracking is designed to withstand harsh environments typically found in construction and industrial settings. The Bluetooth tags and gateways are built to be durable and resistant to dust, water, and extreme temperatures, ensuring reliable performance in any condition.