Safety Incidents

Document, investigate, and analyze workplace incidents and manage OSHA injury and illness reports.

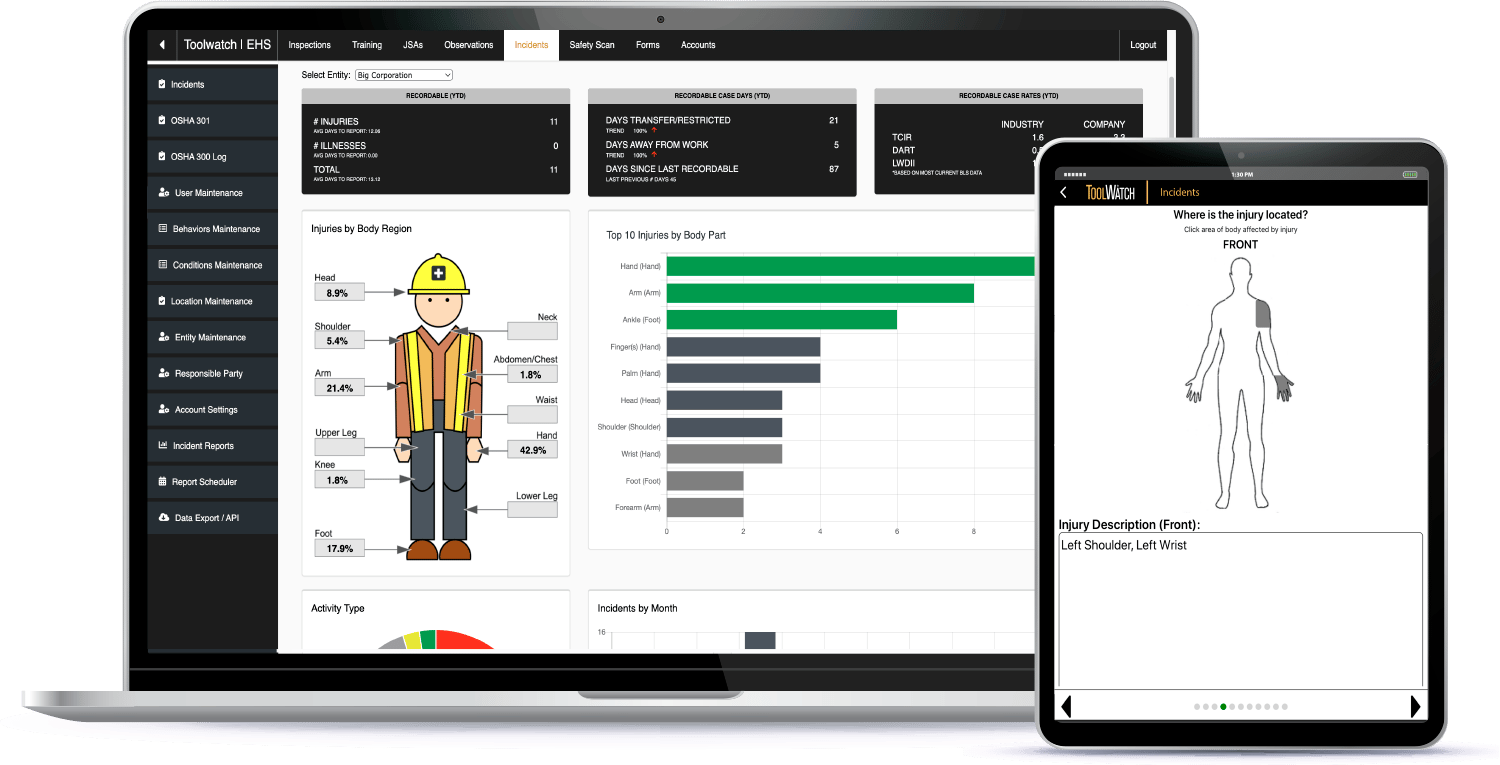

Comprehensive Incident Reporting & Tracking

Easily Document Incidents

Document incident time, location, and type (injury, illness or near miss) as well as what led to the incident, part(s) of the body affected, & more.

OSHA Forms

Easily generate OSHA 300 & 301 forms to document injuries & illnesses quickly.

Causal Factors

Capture behaviors and/or conditions that led to the incident.

Injury Information

Document injury details with the front/back body chart & precise descriptions of affected body parts.

Treatment Administered

Document treatment provided & details about the treatment facility.

Photo Documentation

Capture and upload incident photos with detailed annotations for comprehensive documentation.

Prompt Reporting

Create detailed reports for any incident type in minutes.

Robust Analytics

View trends & identify contributing factors leading to incidents.

Improve Your Incident Response

Real-Time Incident Reports

Powerful Due Diligence

Data-Backed Insights

Customer Testimonials

-

"Pros: Less paper keeps me more organized. The digitized safety forms keep me in the field and more aware of safety. It allows for easier record-keeping and keeps everything fully accessible. Cons: Can't really find any; it allows me more time to keep doing my job while monitoring safety."

Jason G.

Assistant Construction Manager -

"It has created a better experience for our folks around the auditing process as they are more engaged in the process. It also forces them to show their follow-up in the corrective actions area. The module is easy to work through and gives an almost instant report to those who need it, which is greatly appreciated."

Travis P.

Safety Manager

Discover All EHS Management Capabilities

Discover Insights for Success

Accident Causation and Prevention

Contractors can reduce the costs associated with workplace injuries by leveraging accident causation theory to track near misses and identify the root causes of unsafe behavior. In this white paper, you’ll discover the most common causal factors for job site injuries and effective management strategies to mitigate risk.

Download White Paper

How Align Solves Field Productivity Issues

With ongoing labor shortages, many contractors are seeking to "do more with less" by implement operations solutions. The critical solution, according to 52% of construction firms, is investing in technology that prioritizes the needs of their field teams. You can discover how to leverage Align to solve your field...

Download the Guide

4 Keys to a R.E.A.L. Safety Program

Construction is among the riskiest industries, responsible for about 20% of U.S. worker fatalities in 2020. Effective safety programs not only keep personnel safe. They also improve increase the competitiveness of project bids and protect the company's financial health. Discover the R.E.AL keys to building an effective safety program.

Download White PaperSee How ToolWatch EHS Equips Your Construction Safety Program Today

About ToolWatch EHS

1. Will ToolWatch EHS replace Safety Reports?

Safety Reports will continue to be a separate product. ToolWatch EHS is designed for the construction industry, while Safety Reports remain a point solution serving a broader customer base.

2. Our company currently pays for separate ToolWatch and Safety Reports accounts. Can they be merged?

Yes, you can use one login for both ToolWatch and ToolWatch EHS. We will work with you to port your Safety Reports users to ToolWatch EHS so you can take advantage of the benefits of using ToolWatch and EHS together.

3. Does ToolWatch EHS data integrate with Vista? For example, are job or employee data available in EHS from Vista like it is for ToolWatch?

Currently, the primary integration that ToolWatch EHS has is with Procore and PlanGrid. However, we are working so that in the future both ToolWatch and ToolWatch EHS will have the same integration capability.

4. Does ToolWatch EHS offer live tracking of individuals on a job site?

ToolWatch EHS does not not track individuals in real time. However, we make it simple for users to input geotag locations for where they’re performing inspections, observations, or other safety functions. Combined with our time-stamping capabilities, geotag data show when and where certain safety processes are occurring.

5. ToolWatch EHS content is tailored to OSHA standards. Is there a plan to adopt other countries’ standards?

Currently, ToolWatch EHS content focuses on OSHA standards. We are looking to expand our checklist capabilities with additional checklists, detailed comprehensive data and documentation in the future.

6. If a manufacturer has specific inspection requirements, can those be used to direct the inspections for safety equipment?

Yes. Users can customize the inspection checklists and the frequency that you inspect a certain piece of equipment.

7. Will ToolWatch and ToolWatch EHS be accessed with separate mobile apps, or will they be combined?

Today, there is an EHS mobile app and a ToolWatch mobile app, but we plan to have one unified app in the future.

8. What type of access control measures does ToolWatch EHS have?

ToolWatch EHS has controls based on permissions and entitlements. Users can be granted access to individual safety module(s) and/or associated administrative functions.

9. What is the pricing structure for ToolWatch EHS?

The ToolWatch EHS modules come bundled in three different tiers depending on the needs of your safety program. We can work with you to figure out what tier and what modules make sense for you.

10. Can you upload custom sheets/cards for the Toolbox Talks?

Yes. In addition to a library of hundreds of Toolbox Talks that are free for users, companies can upload custom PDF Toolbox Talks to the EHS Training module.

11. Why does ToolWatch EHS use QR codes rather than barcodes?

We are focusing on QR codes because we believe they offer more capability and flexibility to store inspection history and other asset information.

14. Does ToolWatch EHS allow users to track and report on the completion of weekly Toolbox Talks for their crews?

Yes. The ToolWatch EHS Training module allows you to see if scheduled Toolbox Talks have been completed and offers multiple detailed reports that let you filter that information by user and user group.

15. Can ToolWatch EHS be purchased separately from ToolWatch Cloud?

Yes, you can use ToolWatch EHS even if you do not use ToolWatch for other functions.

16. Can Safety Reports data be exported to ToolWatch EHS?

Yes. Any existing Safety Reports data will remain available once you transition to ToolWatch EHS.

Construction firms worldwide trust us with their safety operations

Learn how to transform your safety culture today.